Please note: This page gives a

general coverage of the Jetex 50 series motors manufactured by Wilmot Mansour, Sebel and

Powermax. Two further pages give more detailed information about specific motors:

General Description By far the most popular of all

the motors, more Jetex 50s have been sold and flown than all the other models

combined. This design, introduced in May 1949, has evolved through several versions,

all of which are detailed on this page. What is common to all "50" size

engines is the thrust chamber internal diameter of ~0.560 inch (14.22 mm), to fit

standard "50" size (0.5-in [12.7 mm] dia) propellant pellets. All the 50 size Jetex

engines produce substantially the same thrust, averaging on the order of 1/2 to 5/8 ounce

[14.2-17.7 gm], peaking to 7/8 ounce [24.8 gm], or even higher, at the end of the

run. (In other respects, the Jetex 35 is very similar to the Jetex 50 Export and 50B

models.) Here is a differentiation

summary; each motor is described in greater detail farther below on this page:

The "original standard Jetex 50"

motor had a machined (turned) aluminum alloy case with "ribs," and a turned end cap

assembly. The "export model Jetex 50" and the Jetex 50B both used pressed

cases. Soon only the 50B model was made and sold, and the original models

dropped. The 50B has a slightly longer case, to increase the "free" combustion space

to give better wick-ejection properties. The 50 Hell-Cat is the "standard"

size motor, "fitted with exhaust deflector ring to prevent damage to model through faulty

end cap sealing" (according to contemporary sales literature). Early models did not

have this deflector ring. The 50 HT ("High Thrust") model

also holds two fuel pellets; for test runs or short flights you can use just a single

pellet, which, of course, cuts thrust duration in half. Fuel used in the standard and

HT engines is almost the same; the only difference is that HT fuel has a 1/8-inch [3.2 mm]

diameter hole through each pellet. It is ignited so that the fuel burns throughout

its entire length--not solely on the rear surface, as with the 50 Hellcat. The 50 HT engine has a steel

chamber in place of the aluminum tube of the original Hellcat 50 engine, and is beefed up

in other ways as well. Combinations of fuel may be used in the HT 50 engine.

For example, you can use one HT pellet to give potent initial thrust and get a model off

the ground in a hurry, then in back of it put a Hellcat (standard Jetex 50) pellet, which

will give greatly increased thrust duration and much reduced push. There are many

tricks used to modify the Jetex engine thrust to suit specific models and conditions. Historical Notes Jetex 50 was the third design

introduced, in 1949, by Wilmot & Mansour. It has also been produced in different

configurations by Sebel (UK) and Powermax. Early after its introduction, the

Jetex 50 was somehow modified "for export," and subsequent (beginning about 1953) models

were packed as Jetex "50B" motors. The 50B version produced, according to Wilmot

& Mansour, "25% additional thrust." We are not yet clear on the other

differences between these two models. The current "50C" by Powermax

looks to us almost identical to the "50B" of Sebel; again we are not certain their

differences. The 50 HT model was introduced

early in 1963; it was announced in American Modeler magazine, Mar-Apr 1963, p

21. During a period when Jetex 50

motors were at peak popularity, an American firm designed a variation, sold widely as the

"Psst 50" and "Psst Double-50" motors. These are reviewed separately, as they have very different configuration

(but burn the same propellant). In its current incarnations, the

50 is sold today in the models Jet-X 50C and 50Z, by Powermax. Powermax Jet-X sales

commenced in 1985. Remarks DO NOT confuse the 50

Hell-Cat (sometimes called the "50HC") with the very different 50 Rocket HT (a high-thrust

version, with a different nozzle). 50 Rocket HT propellant pellets are perforated

through their axis with a hole of about 1/8-in [3.2 mm] diameter. They must not be used in the smaller nozzled

50B, Hell-Cat, or similar motors! Specific operational instructions for the "Rocket HT" may be found on another page. Each engine takes two fuel pellets; for test runs or short flights you can use just a single pellet, which, of course, cuts thrust duration in half. The Powermax Jet-X 50Z was

originally identical to the older Hell-Cat 50, with a larger nozzle diameter to accomodate

the higher burn rate and chamber pressures. Suitable Model Aircraft

Performance Specifications Data posted in green is from

original factory packaging and instruction sheets

2: Has a much thicker and metal-reinforced

sealing washer (not suitable for any other engine), and a nozzle exhaust cone that are said

to increase the thrust by up to 25 percent. Uses perforated "Z" propellant pellets,

of which it can hold four. Minimum flights require two pellets. The motor is

gold anodized. Additional Illustrations

Jetex 50 (original issue)

Jetex 50 Hellcat

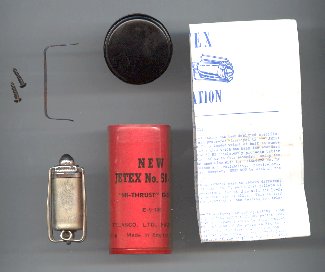

Jetex 50 Rocket HT When the Rocket HT was

introduced, enthusiastic Jetex designers glowingly had this to say: “New vistas of design are opened up. Competition model aircraft should show tremendous improvements in performance, attaining heights and flight-time averages heretofore impossible. Space-type craft with stub wings for safe descent and landing will offer new thrills. Scale ships such as the Lockheed F-104, and even the X-15, now are feasible fliers. Scale Atlas, Thor, Titan and other full-scale boosters can be made to lift off their pads and climb to exciting heights, all in complete safety. Who really can say what ingenious modelers can do with a 500% increase in thrust? What way-out designs will spring from the drawing boards? With the 50-HT to stir things up we will not have to wait long to see.”Specific operational instructions for the "Rocket HT" may be found on another page.

Jetex 50 HT (top) beside Jetex

50 Hell-Cat (bottom)

Jetex 50 Hell-Cat (top, and right) beside an

early Jet-X 50Z (bottom, and left).

Jetex 50C, exploded view, showing components. 1. Motor case

Jet-X 50C

50Z |

......

...... ......

......

...

...

...

...

.....

.....