|

Jetex Rocket 50-HT

Note that photos of

the Jetex 50-HT engine are shown on the Jetex 50 series page. The

Jetex 50-HT fuel pellets have the same

composition as other Jetex 50 propellants. A

1/8” central hole through the

longitudinal axis of the grain provides

increased burning surface, and consequently

greater chamber temperature and pressure, and

thrust. (Hollow-core propellant grains are the

norm in solid fuel engines for both tactical

and space missions.)

The standard Jetex 60

(single-spring) motor should not be used with

the more potent 50-HT fuel. Especially

designed for 50-HT fuel is the double-spring

chamber-sealer, combined with a steel-barreled

chamber. According to older Jetex literature:

“It is interesting to note that the new

fuel, despite its greater thrust and burning

heat, burns cleaner and actually reduces

maintenance.”

Early Jetex

literature also states: “Quick to spot

such possibilities as combining a 50-HT charge

with one of the lower-thrust 50 charges, one

for high acceleration and the other for

sustained duration, resourceful model designers

can work out many combinations tailored to

individual requirements. Additional variations

can be achieved by the different wick

arrangements now possible with the drilled

charges.”

When using the

recommended method of loading (where the

igniter wick is doubled in the pellets and

retained with gauze), a maximum thrust of 5

ounces [142 gm] can be expected with a burning

time of 2 to 3 seconds. Due to propellant

differences, firings may run as long as 3.5 or

4 seconds. If the gauze is left out, both

thrust and burning time will vary widely, with

peak thrust being reached more slowly and the

run lasting longer (but with reduced

thrust).

To attain more thrust

at the cost of reduced burning time, the wick

can be doubled and coiled on the face of the

top pellet, with a gauze fitted. Peak thrust

in this case is reached in a nearly constant

time of two seconds.

By combining one

cored and one plain pellet, with the igniter

wick doubled and retained with gauze, the peak

thrust is reached in about 1.5 seconds, with

the sustainer effect of the plain charge

extending the total burning time or motor run

to about 7 seconds.

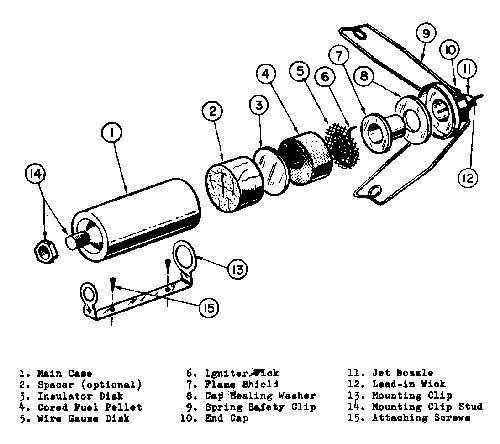

The following is

reprinted from the original instruction sheet

provided with the first 50-HT engines sold by

American Telasco Ltd. [Notes in brackets are

ours.] Jetex Operation

50 “HT”

Reaction Motor: The only motor engineered to

take the new Jetex Super “HT”

fuel.

The Jetex 50-HT high

thrust jet engine has been designed

specifically to handle the higher temperatures

and pressures developed by the Jetex 50-HT

cored fuel pellets. Although its fully loaded

weight of half an ounce is no more than that of

the familiar 50-B engine which has been the

standard model propulsion unit for many years,

the 50-HT consistently produces better than

five ounces of thrust with a duration of up to

four seconds, using the cored 50-HT pellets.

This engine may the used also with the standard

50 solid fuel pellets for superior performance

and reliability, particularly in contest

flying. (The 50-HT pellets, however, MUST NOT

be used in the standard 50-B

engine.)

The 50-HT engine may

be loaded in several ways to obtain different

thrust patterns. When loaded with the standard

No. 50 solid fuel pellets it will produce

slightly higher and more consistent thrust than

will the 50-B, due to the tighter sealing

action of the double spring clips. This is

very helpful in contest flying; and is highly

important in the testing and trimming of any

model.

For testing of

vertical take-off designs, or for operating

such models from small flight areas, a

short-duration, maximum-thrust pattern may be

desired. In this case the setup shown in

Figure 1 would be used. Thrust and duration

will be similar to the left-hand peak of the

graph in Figure 2. Alternatively, by removing

the spacer and insulator disk and using a

stand-ard solid pellet, a low sustaining thrust

will be added to the thrust pattern. This is

shown in the right-hand section of the graph in

Figure 2. This pattern will be found useful

far gaining maximum altitude and duration with

swept-wing or delta designs--particularly under

windy or gusty conditions.

For maximum thrust

AND duration the fuel charge shown in the graph

of Figure 3 will be used. This is an extremely

high performance pattern which will greatly

magnify any maladjustment of the model. It

should not be used until after careful

trimming, balancing, and

testing.

Many multi-engine

combinations may also be worked out, using the

50-HT as a booster unit for high angle

launching or to gain maximum altitude. Because

of its very light weight and high thrust/weight

ratio, its effect on the wing loading of models

designed for larger engines will be of small

consequence. Due to its rapid thrust buildup

and short duration, the 50-HT engine should be

ignited after the main engine to eliminate any

possibility of lapse in effective

thrust.

Further information

regarding the design and operation of all types

of Jetex-powered model will be found in the

booklet “All About Jetex,” on sale

at your hobby store. ENGINE INSTALLATION

1. The mounting clip

should be securely attached to the model, using

both screws and cement.

2. The engine itself

must be held firmly in the mounting clip. Any

looseness should be taken up by bending the

ends of the clip inward to insure a tight

grip.

3. When the engine I

externally mounted, at least 1/4" [6 mm]

clearance must be allowed between the engine

and any combustible material. As an additional

safeguard the adjacent structure may also be

protected with metal foil or thin asbestos

sheet, attached with a non-flammable adhesive

such as water glass [sodium

silicate].

4. Internal

installations should allow 1/2" [13 mm]

clearance all around, plus protective

insulation. Also air venting of the engine

compartment is highly

desirable.

5. Behind the nozzle

some heat protection should be provided for and

inch or two. Beyond this point the rapidly

expanding gases are cool enough to be

safe. LOADING THE ENGINE

1. Before operating

the 50-HT engine, study Figure I to become

fam-iliar with all the parts. Open the engine

by unseating the two spring safety clips (9).

This may be done conveniently by using the

small Jetex screwdriver as a lever [a few of

the early 50-HT engines came with a cute

yellow-plastic handle screwdriver, marked

“Jetex” in red]. Then make sure

that the mounting clip stud (14) and its lock

nut are pulled up tight, as these parts form

the seal at the front end of the main case

(1). Examine the nozzle assembly to see that

the flame shield (7) and the cap sealing washer

(8) are firmly and evenly seated in the end cap

(10). Finally examine the jet nozzle (11) and

if necessary ream it out with the wire paper

clip provided, to remove any machining burrs

[careful here; DO NOT enlarge the nozzle

hole!]. The engine is now ready to be loaded

and operated. (Note that certain replacement

parts such as the spacer insulator disks, wire

gauze disk and cap sealing washer are included

in the 50-HT Fuel and wick

package.)

2. Insert the fuel

charge according to the desired loading

pattern. See Figures 1, 2, and

3.

3. Take about 3" [8

cm] of igniter wick and insert the doubled end

into the fuel pellets an

illustrated.

4. Press the wire

gauze disk firmly in place, with the wick

passing through the edge notch provided for

it.

5. Coil the reminder

of the wick on top of the wire gauze

disk.

6. Place the end cap

on the main case, seating it firmly and even;

then close the spring safety clips. The

screwdriver may be inserted into the loops In

the springs and used as a lever to help do

this.

7. Now snap the

loaded engine into the mounting clip, with the

jet nozzle to the rear of the

model.

8. When ready for

firing, take another 1" [2.5 cm] of igniter

wick and in-sert it into the jet nozzle so that

the inner end will contact the inside coil of

the wick. Not more than 1/2" [13 mm] should

protrude for lighting.

FIRING THE

ENGINE

1. Be sure that the

engine is held securely in the mounting

clip.

2. Push the lead-in

wick in so that it surely contacts the inner

coil of wick.

3. Light the wick,

using a match or any glowing

igniter.

4. Hand launching

should be delayed about two or three seconds,

or until the fuel charge is burning strongly.

A little practice will be helpful in

determining the precise timing at this point.

In static launching, as from a ramp or pad,

support should be provided for at least double

the total length of the

model.

5. In multi-engine

booster operation, restrain the takeoff until

both engines are producing

thrust.

ENGINE CARE AND

MAINTENANCE

1. After firing, one

minute or more should be allowed for the engine

to cool before handling

it.

2. Open the engine as

soon as it is cool and clean all loose ash from

the case, using a wooden stick or dull knife

blade.

3. Clean out the jet

nozzle with the straight end of a paper clip

[gently and carefully!], and scrape all loose

ash from the cap and nozzle

assembly.

4. Examine the wire

gauze disk. If it is not burned out, it may be

put aside for reuse. This part should be

replaced whenever it become so burned or

brittle that it ill no longer fit firmly into

the main case.

5. If the cap sealing

washer is in good condition, the engine is now

ready for reuse. This part should be replaced

whenever it becomes soft or fuzzy, or when

there are signs of power leakage between the

cap and the main case.

6. It is not

necessary to clean the inside of the engine to

a completely bright surface after use. So long

as the fuel pellets fit smoothly into the case,

sufficient cleaning has been done. The LOOSE

ash, however, should never be left in the

engine overnight; it may absorb moisture and

result in destructive

corrosion. |