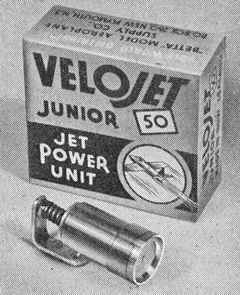

Velojet 50

Illustration source:

Aeromodeller,

Illustration source:

Aeromodeller,

March 1955,

"Trade Notes"

|

|

In March 1953,

Aeromodeller hailed the arrival of the New Zealand designed and manufactured

Velojet 50 and its larger sibling, the Velojet 100, in the following favourable

review:

Motor Mart

announced the existence of a New Zealand Velojet 50 unit last month, and we have now

had the pleasure of testing a sample. Price in N.Z. is 13s. for the 50, complete with

five pellets, wick, gauze and screw mounting clip, and for export this is reduced to us.

A 100 unit is 22s. 6d. in N.Z. — and the same price export. Turned from the solid,

it has many new features. The safety pressure release is at the front in the form

of a disc against a pre-tensioned coil spring, and the screw cap is very easy to re-fit

after loading. Constant use and corrosion make the cap difficult to unscrew

without use of ill-advised pliers. Mounting in an "L" shaped bracket is simple.

It is a very powerful, well-made job, manufactured by the Betta Model Aeroplane Supply

Co., New Plymouth, N.Z.

|

|

|

Tiger Rockety Type A/50

The Type A/50 motor illustrated here used Jetex Red Spot fuel. There was also a Type B/100 motor. Both models were

dimensional copies of their Jetex counterparts.

The manufacturer was

Tiger Manufacturing Inc., 3-1-16 Rokugo, Otaku, Tokyo, Zip 144.

|

|

Ben Nead, owner of the Tiger Rockety Type A/50 pictured here, says of it:

"[My example was] distributed in Australia by Aero-Flyte Products Pty Ltd, Panorama, SA and, curiously, carries the name 'Jet-X' on

the box. I have

seen photos of mint copies of the same motor on ebay

but with Japanese labeled packaging.

"Mine was originally

purchased by a US serviceman stationed in Australia in the late 60s / early 70s. He

bought it in a local hobby shop, fired

it once, but didn't clean it afterwards.

"The entire thing was almost black when I got it. With the help of a

jeweller, I gave it the cleaning of its life. The aft closure cap was

completely covered in black soot and rust which soon gave way

to pitted brass. A mint condition copy of this motor would have

this brass area finished with an electroplating of dark brown

(as opposed to bright red) copper based material.

"The level of workmanship is really

extraordinary. Notice that when it is disassembled, the small dark copper disc comes off

the end of the aluminum casing. The nozzle is supposed to have this copper

plating on it as well. You can

clearly see the pitted brass underneath where this copper plating was

supposed to be."

|

|

|

Nova-Jet

Jim asked:

"Has anybody ever seen the Nova-Jet aeroplane?"

… and Steve Lawrie

sent us this reply:

"Back in the early 60's,

I remember my dad bringing us back two of these planes from a business trip in Europe.

We lived in Johannesburg, South Africa.

"My brother and I each were given a Nova-Jet in its box. I remember it as being made

of white, fairly dense polystyrene foam and was definitely the first molded foam

airplane we had ever seen. It was probably 9 inches long with a span only slightly

smaller. It came with a hand-held catapult whose elastic sling you hitched

to a catch under the nose. The thing flew quite well (but lacked lateral stability)

on the catapult alone.

"I think that the motors were already mounted on the top

middle section of the planes when we removed them from their boxes. I distinctly

remember their shiny aluminium-like feel and appearance: just two parts, the chanmber

and threaded nozzle. The original package did not include any fuel pellets

for these motors, but they worked with Jetex pellets."

|

One other question posed by Jim that we'd like answered is:

- Does anyone have any information about the company name and

patents associated with the company?

If you have an answer, even partial, please

contact us.

|

|

Jim Fackert,

owner of the Nova-Jet motor pictured here, says of it:

"The Nova-Jet

apparently was a delta winged elastic catapult launched glider that

optionally flew with a Jetex-like engine [pictured].

I have the engine and some fuel pellets, but no airplane, and no pictures of

it.

"The fuel pellets were made in Germany, and I

suspect that the whole plane may have been made there…

"The engine is interesting in that it has a threaded-on nozzle and pressure

relief port on the front with a dimpled disk spring that seals the port.

It's a fairly hefty aluminum body with an acme threaded aluminum nozzle cap

and a steel nozzle liner eyelet riveted in."

|

The original instruction sheet was in badly worn condition (see photograph) but Jim has painstakingly restored the text. An extract is reproduced below; the full text is available on a separate page.

FILLING THE JET ENGINE

- Insert the jet fuel pellet (b) all the way into the chamber (a).

- Push the fuse (e) through the jet nozzle (d) and bend it a little, do not break it, at the interior end as shown in the above diagram.

- Screw the cap (c) onto the chamber tightly to avoid gas leakage and push the extending fuse into the chamber so that approximately only 1/4 inch of the fuse protrudes from the jet nozzle. By this method, the fuse is assured perfect contact with the jet fuel, and false ignitions can be avoided.

- Light the fuse and launch the plane as described above.

|

|

|

|

|