Jetex

Motor Manufacturers Checklist

|

Manufacturer

Jetex

(Wilmot Mansour,

UK)

|

Distributors

American

Telasco (NY), sole US

distributor

|

Engine

Model Designations

Jetex Atom 35

(introduced Sep

1953)

Jetex 50

("Standard" May 1949-1954; machined

aluminum alloy, ribbed

casing)

Jetex 50

("Export"; pressed aluminum alloy;

rounded ends)

Jetex 50B

(pressed steel; as 50 "Export" but a bit

longer; introduced Sep

1953)

Jetex Hell-Cat

50 (? This

designation may have only been used

later, for Sebel

motors)

Jetex 100

(1948; 3 coil

springs)

Jetex Jetmaster

(Jun 1952; "100"

size)

Jetex

PAA-Loader 150

Jetex 200

(1948; 5 coil

springs)

Jetex 350

(1948; 5 coils prings, later called the

"Spacemaster 600A")

Jetex Scorpion

600 (introduced Sep

1953)

Jetex

Spacemaster 600A (same as

350)

|

|

Jetex (Sebel, UK)

|

American Telasco (NY), sole US distributor

originally

Aristo-Craft (NY) ???

|

Jetex Atom

35 ???

Jetex

50B ???

Jetex

50C

Jetex Rocket

HT 50 ???

Jetex Hell-Cat

50 ???

Jetex

PAA-Loader 150 ???

Jetex Scorpion

600 ???

Jetex

Spacemaster 600A

|

|

South Shore

Metal Products, Inc. (No. Amityville,

NY)

|

Berkeley

Models

|

Psst

50

Psst Double

50

|

|

Powermax (UK)

|

Powermax (UK)

Davis Model Products

(US)

PVHC (US)

Peck Polymers (US)

Dare Products (US)

|

Jet-X

35

Jet-X 50

(1985)

Jet-X

50C

Jet-X

50Z

Jet-X

100

Jet-X

100Z

Jet-X 100Z Mark

II

|

"Official

Nomenclature"

There are some

"official" terms used to describe the various

Jetex motor parts and components. Here are the

basics, based on a Jetex 150-PAA Loader

engine.

1: Main case (in larger rockets, called

the thrust chamber

2: Spacer (a balsa plug, used when single

fuel pellets are burned)

3: Insulator disc (used between the

single fuel pellet and the

spacer)

4: Pellet (propellant)

5: Jet wick (fuse)

5A: Wire gauze disk (serves as a burn

rate catalyst)

6: Flame shield (protects end cap and

nozzle from propellant burn

heat)

7: Cap sealing washer (this is the

over-pressure safety seal)

8: Spring safety clip (which keeps the

case closed, unless pressure gets too

high)

9: End cap assembly (in larger rockets,

called the "aft closure

assembly")

10: Jet nozzle (only the exhaust hole;

this is not a separate part)

11: Jet wick, lead in (represents the

exterior part of the wick/fuse)

Jetex Motor Specifications

(Comparative)

Data posted in green

is from original factory packaging and

instruction sheets

Data in black is from

our own recent measurements (bold) or other

"non-official" sources

Figures in red

indicate extrapolations, and must be regarded

as approximations at best

|

Engine

Models

|

Thrust

(avg, oz)

[gm]

|

Duration

(sec/

pellet)

|

Duration

(max, sec)

|

Weight

(loaded, oz)

[gm]

|

Weight

(dry, oz)

[gm]

|

Propellant

Wt (min, oz)

[gm]

|

Propellant Wt (max,

oz)

[gm]

|

Total

Impulse (oz-sec)

[N]

|

Propellant

Mass

Fraction²

|

|

Jetex Atom

35

|

0.4-0.5

[11.3-14.2]

|

7-8

|

7-8

|

0.25

[7.1]

|

0.156

[4.42]

|

0.094

[2.66]

|

0.094

[2.66]

|

2.8-4.0

[0.78-1.11]

|

0.62

|

|

Jetex 50

(Standard)

|

0.50-0.63

[14-18]

|

14-15

|

14-15

|

0.36

[10.2]

|

0.25

[7.1]

|

0.11

[3.12]

|

0.11

[3.12]

|

7.0-9.5

[1.95-2.64]

|

0.69

|

|

Jetex 50

(Export)

|

0.50-0.63

[14-18]

|

10-12

|

10-12

|

0.30

[8.4]

|

0.19

[5.3]

|

0.11

[3.12]

|

0.11

[3.12]

|

5.0-7.6

[1.39-2.10]

|

0.63

|

|

Jetex

50B

|

0.50-0.63

[14-18]

|

10-12

|

10-12

|

0.33

[9.3]

|

0.22

[6.2]

|

0.11

[3.12]

|

0.11

[3.12]

|

5.0-7.6

[1.39-2.10]

|

0.67

|

|

Jetex 50C

|

0.75-0.87

[21-25]

|

7

|

14-15

|

0.5

[14.1]

|

0.31

[8.9]

|

0.09

[2.66]

|

0.18

[5.32]

|

|

|

|

Jetex

Rocket HT-50

|

3.5-5.0

[99-142]

|

4-5

|

|

0.5

[14.2]

|

0.375

[10.6]

|

|

|

|

|

|

Jetex

Hell-Cat 50

|

0.6

[17]

|

7

|

15

|

0.4

[11.3]

|

0.2

[5.7]

|

|

|

|

|

|

Jetex

100

|

1.0-1.3

[28.4-36.9]

|

14-15

|

14-15

|

0.875

[25]

|

0.63

[17.7]

|

0.25

[7.09]

|

0.25

[7.09]

|

14.0-19.5

[3.89-5.42]

|

0.72

|

|

Jetex Jetmaster

|

1.75-1.88

[50-53]

|

12-15

|

12-15

|

0.94

[26.6]

|

0.69

[19.5]

|

0.25

[7.09]

|

0.25

[7.09]

|

21.0-28.2

[5.84-7.84]

|

0.73

|

|

Jetex 150

PAA-Loader

|

1.75-2.0

|

7

|

18-20

|

|

0.9375

|

|

|

|

|

|

Jetex

200

|

2.75-3.25

[77.9-92.1]

|

12

|

24

(2)

|

1.56

[44.30] (1)

1.88

[53.16] (2)

|

1.25

[35.4]

|

0.31

[8.86]

|

0.62

[17.72]

|

33.0-78.0

[9.17-21.68]

|

0.66

|

|

Jetex 350

(also called Spacemaster

600A)

|

3.5-4.0

[99.2-113.4]

|

12

|

12

(1)

24

(2)

36

(3)

|

2.75

[78.0] (1)

3.13

[88.7]

(2)

3.50

[99.2] (3)

|

2.37

[67.3]

|

0.375

[10.6] (1)

|

0.75

[21.3]

(2)

1.125

[31.9] (3)

|

42-48

[11.7-13.3] (1)

84-96

[23.3-26.7] (2)

112-144

[31.1-40.0] (3)

|

0.68

|

|

Jetex

Scorpion 600

|

4.0-5.5

[113.4-155.9]

|

8-10

|

12-16

|

2.0

[56.7]

|

1.625

[46.1]

|

0.375

[10.6]

|

0.375

[10.6]

|

32.0-66.0

[8.9-18.3]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jet-X Atom

35 (Powermax)

|

2.5

[70.9]

|

|

|

|

0.106

[3.00]

|

|

|

|

|

|

Jet-X 50

(Powermax)

|

1.2

[40.8]

|

7

|

|

0.353 [10.00]

(3)

|

0.282

[8.00]

|

|

|

8.4

[2.3]

|

0.80

|

|

Jet-X 50C

(Powermax)

|

|

|

|

|

|

|

|

|

|

|

Jet-X 50Z

(Powermax)

|

1.6

[45.4]

|

7

|

|

0.423

[12.00]

(3)

|

0.353

[10.00]

|

|

|

11.2

[3.11]

|

0.83

|

|

Jet-X 100

(Powermax)

|

|

|

|

|

|

|

|

|

|

|

Jet-X 100Z

(Powermax)

|

2.0

[56.7]

2.8

[79.3]

|

7

|

15-26

|

0.846

[24.0]

(3)

|

0.67

[19.0]

0.705

[20.00]

|

0.088

[2.5]

|

0.35

[10]

|

19.6

[5.45]

|

0.83

|

Jet-X

100Z

Mk II

(Powermax)

|

2.8

[79.3]

|

7

|

|

0.776

[22.0]

(3)

|

0.635

[18.00]

|

|

|

19.6

[5.45]

|

0.82

|

|

|

|

|

|

|

|

|

|

|

|

|

Psst

50

|

|

|

|

|

|

|

|

|

|

|

Psst Double

50

|

|

|

|

|

|

|

|

|

|

1: AT = augmenter

tube

2: Dry weight / loaded

weight; a comparison of

efficiency

Lab Reports

A rather intensive

series of scientific tests were made of the

Jetex engine series in 1953-1954, by Ron

Warring for Aeromodeller magazine. This

is the best performance information we've yet

found. The following remarks are based upon

articles titled “Engine Analysis No. 15

(New Series), by Ron Warring, in

Aeromodeller (Nov & Dec 1953, and

Jan 1954), to which we give credit.

Click here to view

"Engine Analysis No.

15 (New Series)"

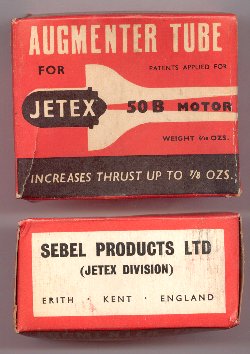

Augmenter Tubes

The makers of Jetex

originally offered two sizes of "augmenter

tubes," which were formed from thin aluminum

sheet; the forward end is bell-mouthed and

considerably larger in diameter than the Jetex

engine (one tube size is for the two 50

engines, the other for the 150 and 600), and

the edge of the bell is placed about even with

the rear of the engine

case.

When the jet is

operating, cool air is drawn into the tube

mouth and is expelled at the tail of the model

along with the hot gases. This air not only

cools the gases but contributes to thrust.

Figures show that the augmenter will increase

thrust from 20 to 30 per

cent.

Ignition is not

difficult with these tubes in place; they

prevent the sparkling fuse from burning the

model interior, too. To work successfully,

plenty of air must be able to reach the forward

end of the augmenter. This accessory is

normally used only inside closed fuselages, as

it would have quite a lot of air drag on an

open-fuselage Jetex-engine

installation.

... ...  ...

...

Jetex 50 augmenter tube kit [click B&W

images to see full-size color

illustrations]

Jetex Jetmaster augmenter tube kit, with

the extension tube made in two parts that clip

together [click image to see full-size color

illustration]

... ...

Jetex PAA-Loader 150 augmenter tube [click

images to see full-size color

illustrations]

Other

Jetex Accessories

Among the curious and

unusual Jetex accessories we've seen is this Dempster Turb-O-Prop, a Techni-Bilt Product from the Dempster Co. in Kansas City. Billed as "the first practical replacement for rubber-band power", it was spun by the exhaust gases from the 50-size pellets burnt in the unit in front of the propellor. One of these sold on eBay in November 2002 for $170.50. Does

anyone know if it

works?

[Click image to see

full-size drawing]

[Click image to see

full-size color

photo]

Rapiers and Other Micro

Rockets

There are several

other kinds of small rockets on the market

today, but none has the features of the

Jetex.

Most notable of these

is the Rapier, similar

to Estes motors in configuration, with

Jetex-like performance. Graham Knight

reports:

" ... they just look

like an Estes rocket, cardboard tube with a

nozzle at one end. Performance, L1 is less

power than a Jetex 50, I guess about 70%, L2 is

a bit more, maybe 110%. I haven't seen an L4

yet but hear it is more power than L2 and burns

longer. Burn time for L1 & L2 is around

20-25 secs. Performance does vary a bit from

motor to motor. If you like Jetex you'll love

these!"

... ...

We've also heard that

there are no mounting provisions accompanying

the Rapiers. However, the instruction sheet

suggests several options, among them the use of

Velcro; gluing the motor to the model; metal

clips; and slipping the motor into a pre-formed

paper tube attached to the

airplane.

"The units are about

the same diameter as schoolroom chalk, 1-1/2"

long for the small units, and 2 inches for the

larger size. Each motor consists of a

cardboard outer casing (about 1/16" wall

thickness) filled with molded propellant.

Unlike the old Jetex motors, Rapiers have no

nozzle. However, like Jetex they are ignited

via a separate fuse, which fits into a hole

molded in the "output end" of each

motor."

The Rapier motors are

made by:

Dr.-Ing. Jan

Zigmund

Jirankova

2281

530 02

Pardubice

CZECH

REPUBLIC

We

received this technical information from Dr.

Zigmund:

Model jet propulsion

units Rapier are designed for recreation and

sport flying to power balsa or paper aircraft

models. The units are manufactured of a card

tube that is filled with pyrotechnic

propellant. On one end the unit is closed with

a refractory nozzle, on the other end with a

refractory cover. Provided the directions for

use are followed, the construction of the units

provides the user with a sufficient safety when

handling the unit. No dangerous fragments of

material fly away from the card tube on a

prospective rupture of a unit. If a rupture of

a unit occurs, the wall of the card burning

chamber usually burns through and the

propellant burns up quietly. Thickness of the

tube is chosen to allow the tube surface to be

heated approximately only to 150°C after

the burn up of the propellant. Interior of the

card tube is charred in so far that its

prospective filling with a home made propellant

leads to a crush of the

chamber.

Model jet

propulsion units Rapier are marked by a low

thrust and long burning time. Dependent on

chemical composition of the propellant it is

possible to obtain burning time of about 20

seconds and thrust ~50 mN (5ponds) at Rapier

L -1 units, and burning time of about 25

seconds and thrust ~75 mN with Rapier L -2

units. L - 1 and L - 2 units are designed to

power chuck - gliders and aircraft models

with wing span 250 - 400 mm and weight up to

25 g. I recommend that the weight of models

should be from 2x up to 3x of thrust of jet

unit in ponds (see performance of jet unit at

the side of a box). The achieved flight times

are 40 - 300 seconds.

Model jet

propulsion units Rapier are analogous to

widely spread JET-X motors that could have

been used repeatedly. Jet units Rapier are

designed, contrary to JET-X, for one flight

only. The possibility of repeated utilization

has been replaced by more comfortable

handling and safer function. The unit is

simply inserted by its front part into the

container fitted to the aircraft model. With

this arrangement the unit is cooled during

the flight and after burnout it is easy to

remove from the container without any danger

of burning. Burning chamber is thrown off

after burnout.

My aim is to offer

the modellers romance and excitement of

flight of jet unit propelled model again. I

would like to let the modellers have a

possibility to experiment and find their own

way to the best construction of an aircraft

model.

My intention is to

produce jet units of L line (series) i.e. for

chuck gliders and aircraft models. The units

will be packed in green boxes and marked with

L letter.

According to

customers’s interest I would like to

produce also modellers rocket motors in

future. They will be packed in red boxes and

marked with R letter to avoid mistaking them

for L units.

I would like to

express my thanks to all modellers and

friends who encouraged me to forward with

development of Rapiers.

|

|

Rapier

L-1

|

Rapier

L-2

|

Rapier

L-4*

|

|

Length (mm)

|

40

|

50

|

50-60

|

|

OD (mm)

|

10

|

11

|

14.6

|

|

ID (mm)

|

6.5

|

7.5

|

10

|

|

Weight, loaded

(g)

|

5.0

|

7.3

|

11.6

|

|

Weight, dry

(g)

|

2.1

|

2.8

|

5.0

|

|

Weight, propellant

(g)

|

2.9

|

4.5

|

6.5

|

|

Propellant mass fraction

(Wp/Wl)

|

0.58

|

0.62

|

0.56

|

|

Duration

(sec)

|

~20

|

~20

|

14-20

|

|

Thrust (avg,

mN)

|

~50

|

~75

|

~150-170

|

|

Total impulse (total,

Ns)

|

~1

|

~1.75

|

~2.5

|

* in

development

Dr. Zigmund's letter

also refers to the Czech certification of the

motors and fuse (Decision No. 214 - 99 - 0167/V

06317 was rendered on August 12, 1999 by the

Authorized State Testing Laboratory No. 214

VVUÚ a.s., Pikartská 7 716 07

Ostrava - Radvanice, Czech Republic: to

certify "Model jet propulsion units RAPIER"

At the same time decision No. 214 - 99 - 0168/V

06318 was rendered to certify "Fuse type 07"

designed for Rapier

units.)

Thank you, Dr.

Zigmund. We're now converting his Standard

Units to a more familiar British Units, for

ready comparison to Jetex

specifications.

There are several

other kinds of small rockets on the market

today, but none have the features of the

Jetex. All of the other reloadables are

bigger--much bigger. And all the rest of the

small rockets are really high-impulse boosters,

offering nothing in the way of sustained

power.

This illustration

shows both the Apogee 1/4-A and the Estes B

sized conventional (high thrust, short

duration) model rocket engines. The Apogee

1/4-A motors, propelled by black powder, are

quite light and effective when a very short

burn time can be applied. The B size motors,

also with black powder, are the next step up in

physical size and performance. These two

motors represent the main alternatives to Jetex

propulsion in micro rocket sizes. Great for

their own special (ballistic) applications,

neither work well for freeflight

aeroplanes.

[click image to see

full-size graphic]

This graph shows the

thrust curves for several common 1/2-A through

D size conventional small rocket motors. Note

the thrust is at best one or two seconds.

1/2-A motors produce a total impulse of about

0.28 pound-seconds (1.25 Newton-seconds). The

larger D motors produce a total impulse of

about 4.5 lb-sec (20 N-sec), and reach nearly 7

pounds at peak thrust. The largest Jetex

engines produce perhaps 6 ounces of thrust, for

perhaps 15 seconds.

NAR

Standard Model Rocket

Classifications

Larger rocket motors

are customarily rated by their thrust and burn

duration, the product of which is called their

"total impulse," and is often rated in

pound-seconds. This refers to the equivalent

amount of forward thrust the motor produces, in

pounds, if all the propellant burned for one

second. Thus a motor with 500 lb-sec total

impulse might burn at 100 lbs thrust for 5

seconds, or 1 lb thrust for 500 seconds. The

important thing to remember is that "total

impulse" refers to total thrust yield over the

burning duration; this is not the same as

average thrust (unless the motor happens to

burn exactly one second).

Total impulse is the

starting point for determining a rocket

propellant's efficiency, which is called

"specific impulse," or Isp. Specific impulse

is the total impulse (power generated) of the

propellant divided by its weight. This number

is measured in "seconds."

Thus, a motor which

produces 500 lbs thrust for 1 second has 500

lb-sec total impulse. If this motor burns 5

lbs of propellant to produce this thrust,

then

500 lb-sec / 5 lb =

100 lb-sec/lb, or 100 sec

Accordingly, 100 is the

Isp of the propellant burned. Black powder

produces an Isp of less than 100, while advanced

composite (polymer-fuel) propellants produce Isp

ratings of nearly 300. The higher the Isp, the

higher the thrust x time per pound

burned.

Model rocket motors

have long been classified by a standard adopted

by the (US) National Association of Rocketry.

These apparently arbitrary classifications have

proven useful for both standardization of motor

sizes and performance, and for safety

classifications by

legislators.

For many years the

only model rockets produced were of the A, B,

C, and D classifications, which produce less

than 20 newton-seconds (or about 4.5

lb-seconds) of total impulse. More recently,

smaller and larger motors have reached the

market, including the new Micro-Maxx (by Quest)

which is rated at 1/8A, and produces less than

1 ounce-second of total impulse. The largest

commercial "model" rockets today go into the M

and N classes, and produce hundreds of

pound-seconds of total

impulse.

Jetex motors fall

within the A through D classes shown in the

table below, based upon their total impulse.

Jetex 50 is an A class motor, for instance,

producing about 0.5 ounce thrust for about 15

seconds, or a total of 7.5 ounce-seconds total

impulse. The "big" Jetex 600A Spacemaster

produces over 200 ounce-seconds of total

impulse.

Note that the NAR

motor classifications are based only upon the

total propellant impulse, as measured in

newton-seconds. A newton-second is the thrust

force of one newton operating over a one second

period of time. (1 lb = 4.448 newtons; 1 oz =

0.278 n; 1 gm = 0.0098

n)

NAR Standard Model

Rocket

Classifications

|

Rocket Motor

Classification

|

Total Impulse

(newton-seconds)

|

Total Impulse (gram-seconds,

±)

|

Total Impulse (oz-seconds,

±)

|

|

1/8A

|

0--0.31

|

0--32

|

0--1.125

|

|

1/4A

|

0.32--0.63

|

32--64

|

1.125--2.25

|

|

1/2A

|

0.64--1.25

|

64--128

|

2.25--4.5

|

|

A

|

1.26--2.50

|

128--256

|

4.5--9.0

|

|

B

|

2.51--5.00

|

256--512

|

9--18

|

|

C

|

5.01--10.00

|

512--1024

|

18--36

|

|

D

|

10.00--20.00

|

1024--2048

|

36-72

|

|