|

[shown actual size]

General

Description

Together with the

Spacemaster 600A, the Scorpion 600 is one of the most powerful Jetex motors ever

built. It has an aluminum engine chamber, and is fitted with a nozzle cap assembly

that can be disassembled in part. All in all, the design is quite excellent, and this

motor has been very popular for larger freeflight models.

Unlike other models,

the motor has a built-in mounting tube on the forward end, to permit easy attachment to a

vehicle. The roller-spring clip assembly uses a double set of five leaf springs, one

set on each side. These leaf springs appear identical to those used on PAA-Loader 150

engine. The motor clips, of which there are two, appear thus to be somewhat shortened

versions of PAA-Loader motor clips, used in tandem.

The Scorpion 600 uses

pellets with a conical depression on the "hot" end, to increase burn surface, chamber

pressure, and thrust. A special coned washer ensures positive contact between the

igniter wick and the pellet. Only one charge can be fitted, giving a thrust of 6

ounces [170 gm] for about 8-10 seconds.

Historical

Notes

The Scorpion was

introduced in Sep 1953 (Aeromodeller, p 517), and was later distributed in the US by

Aristo-Craft Miniatures, and perhaps also by Peck Polymers.

Remarks

Shallow fins are

produced around the motor chamber circumference, improving engine radiant cooling.

The Scorpion uses propellant pellets that have a coned surface on the front face,

with the gauze disc coned to fit. The purpose of the coned pellet end is to enlarge

the burning area and increase thrust.

Construction of the

motor was, in the words of Wilmot & Mansour, "a compromise between the earlier and

latest methods of manufacture. The main case is turned from a special aluminium alloy

complete with rings ["ribs," or "fins"], etc. The end cap is a stainless steel

pressing and the sealing washer and flame shield are retained by the screwed jet and jet

collar, which are made from mild steel."

The end cap is sealed

with a duplication of the Jetmaster spring assembly. Two saddles tensioned with leaf

springs are fitted, and these snap onto a special yoke pressing on the mounting end of the

motor. The actual motor mounting consists of a thin-walled aluminium alloy tube,

screwed to the end of the motor, which is a good press fit into another tube fitted into a

balsa block which can be cemented in place on the model.

Suitable Model

Aircraft

Wingspan (in)

[cm]

|

35-45 (52 in some

designs)

[89-114; 132]

|

Wing area

(in²)

[cm²]

|

175-200 (320 in some

designs)

[1129-1290; 2065]

|

Weight (max,

oz)

[gm]

|

12 (14-16 with AT)

[340; 397-454 with

AT]

For contests, use half these

figures

|

Performance

Specifications

Data posted in green

is from original factory packaging and instruction sheets

SI (metric) units

provided in brackets

Data in red indicates

extrapolated information, and must be regarded as approximate, at

best

| Thrust (avg, oz)

[gm] |

5.5-6.0

[156-170]

(4.0-6.0) [113-170]

|

| Thrust (max, oz)

[gm] |

6.0

[170]

|

| Thrust w/AT¹ (nom, oz)

[gm] |

7.0-7.5

[198-213]

|

| Duration

(sec/pellet) |

8-12

|

| Duration (max,

sec) |

10-12

(12-16)³

|

| Weight (dry, oz)

[gm] |

1.56

[44.2]

|

| Weight (full, oz)

[gm] |

2.0

[56.7]

|

| Propellant (min, oz)

[gm] |

0.375

[10.6]

|

| Propellant (max, oz)

[gm] |

0.375

[10.6]

|

| Total impulse (oz-sec)

[N] |

~44-72

[12.2-20.0]

|

| Specific impulse (Isp,

sec) |

117-192

|

| Propellant mass

fraction² |

0.42

|

| Length (in) [cm]

|

2.25

[5.7]

|

| Width (max, in)

[cm] |

1.75

[4.45]

|

| Chamber ID (in)

[cm] |

1.00

[2.54]

|

| Throat (in) [mm]

|

|

| Burn surface (nom, in²)

[cm²] |

0.78

[5.03]

|

| Operating pressure (psia)

[atm] |

|

3: Reported by

some, perhaps for later fuel compositions

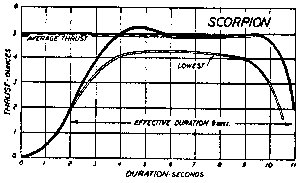

This is a laboratory thrust curve showing

Jetex Scorpion 600 performance. This is a laboratory thrust curve showing

Jetex Scorpion 600 performance.

From Aeromodeller's extensive test report, Nov 1953.

Click image to see enlarged graph

Additional

Illustrations

The Scorpion engine has a forward mounting

tube, which fits over a post in the model.

Note that the aft-closure assembly,

including the twin spring clips, cannot be completely disassembled. The nozzle

portion of the closure, however, can be unscrewed from within.

This exploded view of a scorpion shows the

several parts used in this more complex design. (Click image to see more

detail)

This old ad, from American Telasco, shows

the features of the Scorpion.

A handsome package from American

Telasco. Engine by Wilmot, Mansour.

|