|

Jetex 50 – one motor, many variants

|

As the most popular unit of the range, the Jetex 50 underwent a series of modifications in order to keep pace with new developments.

|

|

|

Original standard 50 – first of the line

|

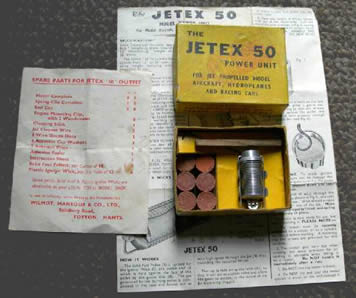

The original standard 50, now much sought after by collectors, had a turned ribbed main case and end caps.

Sensing a demand for a smaller addition to the range, Wilmot Mansour brought it to the market in their second year of production, in 1949. Production was eventually phased out in favour of the later versions, in 1954 (see ‘50B morphs into 50C’ below).

The original utilitarian packaging (below and upper right) was soon replaced by a styling that would come to be recognised as distinctively Jetex (lower right).

|

|

|

|

From 50 to 50B

|

In the U.S.A. the most popular unit was the Export 50, from which was evolved the 50B. Both differed from the standard 50 in that they had a pressed alloy case, rather than a turned one, and dome shaped exhaust nozzles, which had proved more successful with augmented thrust experiments, but necessitated a flat asbestos bottom shield. An additional improvement in the 50B was its greater length, providing more free space for combustion and aiding wick ejection.

The next development was the packaging of the 50B motor with an augmenter tube (right). This was a great boon to scale model enthusiasts, who were now able to fully enclose the motor and have it exhausting in realistic fashion through the scale jet nozzle.

|

|

|

|

50B in French costume

|

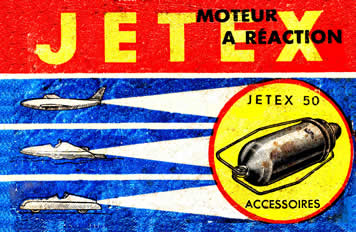

Jetex built a keen following in France, and 50B motors were manufactured there under license by Solido in freshly designed packaging (right), with the brighter blue possibly intended to evoke a deliberate echo of the French tricolour.

Instructions were specially written in French (below).

|

|

|

|

50B morphs into 50C

|

To cope with the increased heat and pressure of their own fuel, Sebel manufactured a new version of the 50 motor, with the same shape as the 50B, but using steel throughout. While this gave it increased durability, it still required as much attention as the 50B (if not more) in order to avoid corrosion.

1. Motor case

2. Exhaust deflector ring

3. Solid fuel pellets

4. Gauze disc

5. Igniter wick

|

6. Flame shield

7. Cap sealing washer

8. Wire clip

9. End cap

|

An innovative feature of the 50C was the addition of a collar-like exhauset deflector (2), intended to protect the model against blow-back, a common fault on the small lightly sprung motors. However, the collar tended to foul on the spring.

Also introduced with the 50C was a new motor mount, completely enclosing the motor and affording greater protection with internally mounted units.

|

|

Jetex 50C in Sebel packaging

- David Ranford

The final transformation of the Jetex 50 was into the 50R (50HT in the US), in an attempt by Sebel to cater for a growing band of model rocket enthusiasts. (We devote a separate page to this specialised variant of the Jetex 50.)

|

|

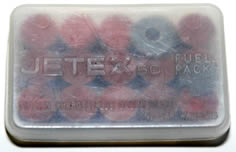

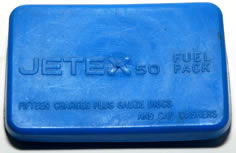

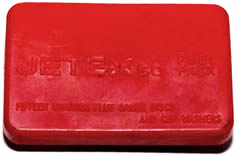

Jetex 50 Fuel Packs

|

Fuel pellets for the Jetex 50 appeared in a variety of separate packs over the years. Those illustrated here were all produced by Wilmot Mansour at various times.

Each pack contained 15 pellets (called ‘charges’ on the box lid), together with two spare gauze discs (each with a cutout for the fuse to pass through) and two additional asbestos cap washers.

|

|

|