|

|

|

|||

|

|

||||

|

|

||||

| The Smoky Addiction | ||||

|

|

HOME | SITE MAP | FORUM | CONTACT |

|

||

|

ABOUT | MOTORS | MODELS | ARCHIVE | HISTORY | STORE | FAQ | LINKS

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Smoky Addiction 6

(June 2005)

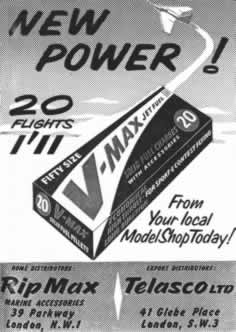

by Roger Simmonds Reprinted from SAM 35 Speaks, June 2005 A A (Bert) Judge’s mid-sixties’ memo to Jetex management (see April’s SA) covered, amongst other topics, the impact of V-Max pellets and ICI’s rising prices on Sebel’s R & D. I was uncertain whether V-Max pellets were ever widely available in the UK, but the advertisement on the right from a contemporaneous Aeromodeller shows that they were, and cheaply. Has any reader experience of V-Max pellets or any examples in the loft? Their use in the Jetex 50B was, according to Bert, most ill advised, and marketing such a dubious product was irresponsible, to say the very least. After the demise of Jetex, Bert was approached by Cambrian Models, who were exploring a possible relaunch. Here’s Bert’s tale verbatim: “They wanted me to act as consultant and went into what was involved with the manufacture of the fuel and into the costs and everything. One of the first things they wanted to know was: how to produce the fuel and wick? […] So I told them I could supply the fuel and the wick formula and how it was done at Erith […] One of the ingredients is gum acacia to bind everything together, so a lot of small ingredients are mixed up first in a ‘Y’ blender in one operation. “Next the guanidine nitrate has got to be a certain size, so that goes into another ‘Y’ blender for a time. You then blend the two powders together, mix for a time, and then that goes into a pelleting machine with a big vibrating open hopper. That goes down via a sweeper into a die so that the moulds are filled. Then your pelleting machine comes down. The mixture is compressed from the bottom and top in order to get the compression right and get equal pressure. After this the pellets come off and are fine water sprayed. We had to do that because the potassium dichromate is a nasty substance. They then fall onto an endless heated belt for five cycles, so that by the end they are completely dry and hard and can be packed. […] The cost of this machine was colossal. […] That effectively stopped [Cambrian’s] enterprise.” Thanks again are due to Andy Blackwell for preparing the transcript of our interviews with Bert, from which the above is taken. The complexity of the process and the expertise required help explain why Sebel fuel remained comparatively expensive and why other manufacturers looked at different processes with alternative ingredients in order to compete. Though all the techniques and formulations have now long been in the public domain, and there is nothing to stop anybody producing an exact copy of the original Jetex pellets, this is a daunting task even today and the investment required would be considerable. Bert’s story also emphasises Jan Zigmund’s achievement with Rapiers. These remain, so far, the only sustained-thrust rocket motors on the market. |

- Aeromodeller, July 1957

- eBay seller ‘bellhobbys’, May 2005

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Though the specification (thrust and duration) of each batch of Rapiers is carefully marked on the box, it has been a bit of a puzzle as to how exactly these are measured, since they sometimes bear only a passing resemblance to the motors’ actual performance on the flying field. I don’t know of any publication where Jan’s methods have been described. Howard Boys was much more forthcoming in a report published under the aegis of the LSARA, and also in ‘Rocket Models’ (Aeromodeller, July 1947, see right). This seminal article (and remember this was a year before the introduction of Jetex) included thrust graphs for the ‘No 1A’ and ‘No 3’ R. P. units [below]. How these were produced is explained in LSARA Report No 31, ‘A Thrust Recorder for Testing Model Rockets and Various Results’. A brief review of this publication (which was kindly passed to me by the editor) may encourage a scientifically minded reader to attempt similar experiments with Rapiers. |

- Aeromodeller, July 1947, p. 466

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||

It is interesting to note that, like other LSARA reports of the time, this had restricted circulation and the warning, ‘Not to be divulged to any person who is not a member until the first of June 1948’ appears below the title. No doubt Jetex, who were indeed members of the LSARA, knew of its existence, and it may have influenced their own methods of measuring thrusts. HB’s rockets were: the 1A, ½" long, “It became obvious at an early stage that some means of accurately measuring the thrust of the various early units was required. This report describes the stages in the evolution of a suitable device. The first units were tried on a small spring balance, but the thrust varied more than had been expected. The next attempt was to mount a lever on a vertical pivot with a pointer on the end. The rocket was mounted on a lever with a spring to balance the thrust. The scale was calibrated with weights and during the burning of the charge I called out the readings to my wife at regular intervals, who wrote them down. The duration was timed with a stopwatch and a rough graph plotted. The pointer oscillated too much for this method to be satisfactory.” HB then developed the ingenious, if somewhat Heath Robinson, apparatus shown below. Here the motor plots the graph directly onto a revolving drum. It doesn’t look too difficult to replicate. Would anyone with an engineering background like to try?

|

- Aeromodeller, July 1947, p. 466

|

|||||

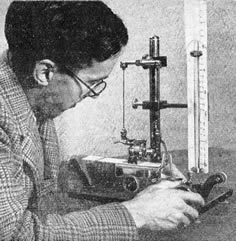

It is not as well an engineered instrument as the one devised by Joe Mansour and his team (shown on the right in the capable hands of R H Warring; see also (Jet)X Files 17, May 2004); but HB was nevertheless able to generate some useful data. The graphs published in the Aeromodeller for the general reader were cleaned up considerably, and the rather messy traces actually obtained with the smaller motor, as originally published in the LSARA report, are show below for comparison. HB summarised his findings thus: “There is a considerable scatter between the separate units but it would seem that the 1a unit gives an average thrust of 0.6 oz for six seconds and the no 3 unit gives 2½ oz for 13 seconds … a later version of the 1a unit, now on sale, gives 0.8 oz thrust for about five seconds.”

The founder of the LSARA, N K Walker, obviously wished to add his imprimatur to such an an innovative report, and the final section is entitled ‘Comments by the Director of Research’. In Walker’s opinion, the high peaks seen at the beginning of a test were not a true record, but were an artefact caused by overshoot, and he recommends the addition of an oil bath to damp the arm. The Jetex thrust rig, you will remember, used hydrodynamic damping, though it lacked a recorder. Walker notes that the specific impulse (SI, defined as thrust × duration / weight) was only about 18, not very high in comparison to JATO cordite motors (180-200) and he was sure an SI of 80 could be achieved with a more modern propellant. It is pertinent here to record that Jetex motors (and Rapiers) have an SI of 35-45 or so. Walker then had this to say about the motors’ construction: “The venturi of the 1a unit (a constriction of the cardboard case) is not really very satisfactory since the thrust line can be 10 degrees offset to the axis of the rocket and the degree of offset varies during the run, which make accurate trimming of the model impossible“. Now, where have I heard that before? |

- Aeromodeller, Nov. 1953

|

|||||

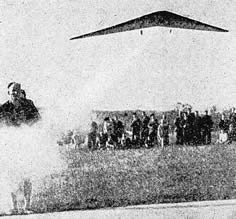

|

However, Walker concludes, perhaps with some foreknowledge of Jetex: “It would therefore seem that the existing rocket units will never be serious competitors to the petrol or diesel motor, but it should be possible to construct a light gauge steel case with removable venturi and separate charges which could give as much thrust for 10-15 seconds as a small diesel motor. Such a unit, with electric ignition, would prove a serious competitor to the petrol motor, on the score of absence of torque, novelty, greater convenience, and cheapness.” Hmm… it didn’t quite work out like that. We still await reliable electric ignition; flying rocket planes will never will be cheap in terms of cost per flight; and, alas, the novelty, except for the chronically addicted, soon wore off. However, the R.P. units were a lot of fun whilst HB kept ahead of the authorities and they were available. The photo of HB with his large Flaming Ptero (above right, taken from the Aeromodeller article) is proof they could give spectacular results. My admiration of Howard Boys continues to grow; he obviously took a lot of care over the development of his innovative motors, which are the ancestors of today’s Rapiers, and he did manage to market them, albeit for an all too brief period. It would be good to see more of his designs flying again, the ‘Astral Rocket Plane’ and the lovely Vampire in particular. It is ironical that some of the problems seen with his R.P. 1A motors have reappeared with Rapiers. I suppose it could be argued it all adds to the authenticity! |

- Aeromodeller, Jul. 1947

|

|||||

|

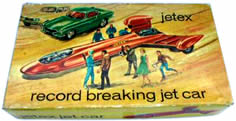

Bert Judge’s historic memo also referred to his latest three-wheeled RTP car for the 50C. Nigel Smalley spotted this one on eBay. [Colour images are needed to do justice to] the colourful attractiveness of the box, [and] the equally alluring bright red futuristic product inside. I have a great nostalgia for these last products of the old firm, though (or because) I couldn’t afford them when they first appeared. I can’t afford them now, either, as Jetex memorabilia these days are snapped up by ‘collectors/investors’ with deep pockets. The ‘Antiques Roadshow’ has a lot to answer for. There were three Jetex RTP cars in all; this last one looks like it could well have taken to the air given half a chance! Recreation should not be too difficult, using the techniques Terry Kidd described with respect to the Lynx, (SA, March) but we do need a reasonable example to work from. I may have done Mike Hardy a disservice in last month’s article, as I had assumed his ‘restoration’ of Ian Dowsett’s vintage Hot Dog plan involved a computer aided design (CAD) package. I’m not sure why, but I was very pleased to find Mike had used traditional drafting techniques, and a very nice job it is too. Please let me know if you would like a photocopy of this genuine dyeline print. Mike’s replica Hot Dog is traditionally powered with an antique 50B motor (see last month), but the model is equally suitable for Rapier L2 as long as the underside of the fuselage is well protected from the hot and dirty exhaust.  Mike Hardy’s dyeline print of Ian Dowsett’s first kit for the Jetex 50 There is nothing wrong with CAD of course, and drawings can be accurately prepared and manipulated much more easily in the electronic realm – if you have the necessary skills. And there’s the rub: I haven’t, and I admire those who can turn out these works of art – with apparently effortless ease – enormously. The admirable Steve Bage has already produced sets of drawings for his Yak 25 and MiG 21, so please contact him if you would like copies; another advantage of CAD is that accurate reproductions are easily printed off, or cloned computer files can be distributed across the aether. |

- as sold on eBay, March 2005 for £103.56

|

|||||

Steve has now turned his attention to a 1950s ‘might have been’’, the Hawker P.1121 Mach 2 fighter/bomber – see photo right and plan below: Steve has also made a preliminary study of another fifties’ jet for which I can find no contemporaneous design: the mighty Thunderchief:  The ‘Thud’, as it was known, presents some interesting challenges to the modeller, for example a ventral fin that is in the direct path of the motor exhaust. This is also an unfortunate (scale) feature of the MiG 21. Steve has now flown his MiG 21 (a photo of which appeared last month) and writes: It flies in a nice steady fashion on a 110 mN rated Rapier L-2 and zips around like a scalded cat on a 220 mN(ish) L-2HP. On high power it tends to climb very steeply near the end of the motor run, which results in a big stall at ‘flame-out’. Given some more trimming flights, I can most likely get around this […] or failing that I might just stick with slightly less powerful motors, the L-2HP is really way ‘over the top’ for a 29 g model anyway. The removable ventral fin needs to be clad with aluminium foil […] I tried just painting it, but the heat just blistered all the paint off. |

- Steve Bage

|

|||||

|

Mind you, a foil-clad ventral fin might not last very long either. The Thunderchief’s fuselage is quite slim, and the trough, which Steve has made deep enough to hide the motor, will inevitably be quite narrow. Also, whilst the trough’s angle provides a measure of downthrust (always helpful in achieving a stable flight pattern), this too will make it very vulnerable. We obviously need an alternative heat resistant material for troughs. And ventral fins. One possibility is a new ceramic cloth called ‘Fiberfrax’. This high-tech aerospace product should, according to the manufacturer’s specification, withstand the heat and blast more or less forever. I hope Ben Nead will bring me an example when he visits for the Solent Sky Exhibition, and I will divulge the results of my experiments in due course. |

||||||

|

|

||||||

|

|

|

|||||

|

|

|

|

|

|

|

|

Acknowledgements - Article: Roger Simmonds - Illustrations: Roger Simmonds, Steve Bage, Mike Hardy, Bill Henderson, MAAC archives via Bill Henderson, Nigel Smalley |

|

|

|

|

ABOUT | MOTORS | MODELS | ARCHIVE | HISTORY | STORE | FAQ | LINKS |

|

|

Terms of Use

|

Queries? Corrections? Additions?

Please

contact us.

|

|